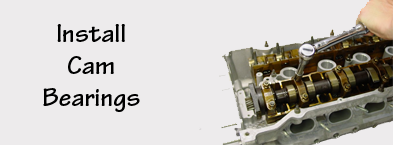

It’s easy to overlook the detailed process that goes along with building a reliable mill from the ground up. Much of the time the engine shop will handle most, if not all, of the prep work. This would include honing the cylinder bores, decking the surface, align-honing the main caps, and even installing the camshaft bearings. Most reliable machine shops make these otherwise unseen jobs, effortless. Although not everyone has the understanding or tooling to machine a block, installing a set of camshaft bearings can be accomplished with some basic knowledge.

Considering the bearings support the twisting load of the camshaft and act as a protective shell, it’s no wonder more enthusiasts leave this task to a professional builder. Factoring in the bearings’ job, installing a set can seem like a task that only the most experienced can handle. However, we’re here to tell you even the most timid wrenchers can tackle this task with confidence.

With the right information, you don’t have to be a seasoned veteran to learn what’s involved with installing a set of camshaft bearings on your own. In short, once the bearing is lined up in the journal, it’s just a matter of knocking it in. It’s also important to note that nothing stops the bearings from being hammered in too far, or even all the way out the other side. Therefore, frequently checking the position of each bearing will ensure the correct fit.